Electric motors generate motive power using magnetism. The methods differ, whether using the force created by actual magnets attracting and opposing one another, or by manipulating the magnetic field inside the motor with current, but the principle remains the same. While many car owners can wrap their heads around how a gas engine operates and creates motion, fewer of us have a firm grasp on how electricity makes a car move. Most of us understand it takes a larger battery that requires recharging, but beyond that is a landscape of words and terms — current, induction, permanent magnet, synchronous, asynchronous — that could make you wonder if owning an EV, or at least understanding the one that you might buy, requires an electrical engineering degree. Fortunately, it doesn't. Just like diving into the intricate workings of a regular combustion engine, it's easy to get lost in the weeds of how electric motors work. Now, let's get into the weeds ...

How Electric Car Motors Work

Am I Ready for an EV?

- EV ownership works best if you can charge (240V) at home or at work This typically means a 240V home installation, but you could also have a similar setup at your office or other places your car is already parked for several hours each day. Don't expect a regular household outlet (120V) to suffice unless you've got a plug-in hybrid, in which case overnight charging at home is feasible.

- If you can’t charge at home, charging at a charging station could take at least 10x longer than at a gas station With public charging infrastructure still in its infancy, the user experience can be maddeningly inconsistent. Tesla owners tend to rave about the reliability and speed of the company's proprietary Supercharger stations, but rival DC fast options have thus far been plagued by technical issues and overcrowding. It's an evolving landscape and our best advice is to do your research on the available options for the EV you want to buy.

- Adding a 240V home charging system could cost up to $1,600 or more If your existing electrical service can handle the additional demands of EV charging, you may be able to add Level 2 charging at home for less than a grand, including installation. But your costs will multiply if you need to upgrade your electrical panel or add a dedicated circuit.

Basic parts and principles of electric motors

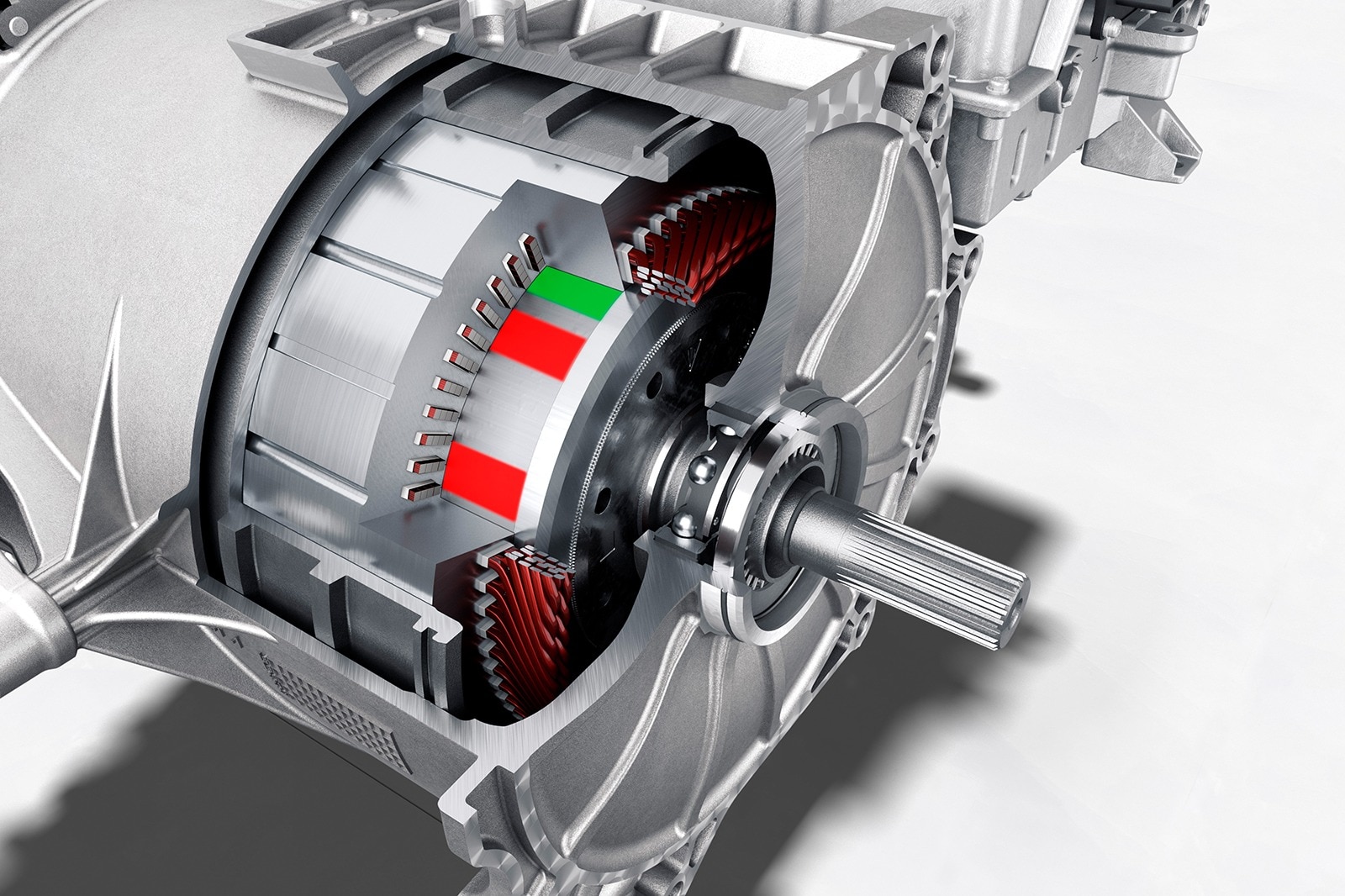

An electric motor consists of two basic components: a stator and a rotor. The stator is a round housing with magnets or coils inside, while the rotor is the rotating piece, or assembly, that spins to generate motive power, similar to a crankshaft in a gas engine. When the driver presses the accelerator, the battery sends current to the stator, which energizes the rotor and causes it to spin. That rotation causes the gears to turn and transmit power to the wheels.

Taking your foot off the accelerator sends energy back in the other direction. Electric motors are not only propulsive motors but also generators, and they are capable of returning energy to the battery. This process is called "regenerative braking." It is similar to engine braking on a gas-powered car, where downshifting uses the transmission to slow the vehicle down. In the EV's case, however, that energy can be recaptured by the battery, recharging it rather than being burned off as waste heat and exhaust.

How do electric motors differ?

There are several types of electric motor designs, but most modern EVs use either an asynchronous or a synchronous design. In an asynchronous motor, the rotor tries to keep pace with the stator's spinning magnetic field. It's this offset, or "lag," state that generates high power characteristics. In a synchronous motor, as its name suggests, the rotor turns at the same speed as the rotating magnetic field, making it well suited for forceful torque at low speeds.

Synchronous motors: They generate a magnetic field when the wires inside the stator housing receive alternating current (AC) from the battery (or more specifically, the power inverter that translates direct current — DC — from the battery into the alternating current that the motor requires). The magnet-covered rotor then keeps pace with the spinning magnetic field. You'll often hear these referred to as "permanent magnet" motors.

Asynchronous motors: Also called "induction motors," these also generate a magnetic field when fed current, but the rotor is "induced" to follow along by its own set of magnetic wires and windings. In other words, imagine the spinning vortex of magnetism "dragging" the rotor along with a slight lag rather than moving in lockstep with it, as a permanent magnet motor might.

Both designs have their pros and cons. Asynchronous motors, credited to inventor Nikolai Tesla, are relatively cheap and simple to make, but they're harder to fine-tune. Synchronous motors are easier to dial in with more precise output by adjusting the amount of alternating current, but they're also heavier, more complicated and more expensive. They also use magnets made of rare-earth materials, which EV opponents can use to make an argument regarding efficiency and sustainability.

Understanding electric motor output

Most car owners understand the idea of horsepower, quaint as it seems now in the 21st century. We're now in the midst of recalibrating our understanding of motive power in the era of the electric car. An EV motor's power output is rated in kilowatts, which roughly mirrors our understanding of horsepower. The Nissan Leaf's motor, for example, is rated at up to 160kW, a relatively modest amount compared to the Tesla Model 3's 397 kW. When converted to horsepower, the Leaf makes up to 214 hp, while the Model 3 tops out at around 425 horsepower. The rough formula is 1 kilowatt equals 1.34 horsepower. As with anything metric in this country, this may take a while to catch on, if ever, with American buyers. For now, just know that an EV's motor output is often expressed in kilowatts, alongside a traditional horsepower rating.

Simple in operation, simple(ish) to understand

Love or loathe them, electric vehicles are here to stay. EVs can help reduce tailpipe emissions and dependence on fossil fuels, especially with motors that require minimal maintenance, including the absence of oil changes. EV motors need only a bit of grease to keep some rotational parts lubricated. Fewer moving parts and pieces mean fewer parts to wear and fewer parts to break. Compare that to your average internal combustion engine car with its many belts, hoses and fluids and you can understand at least some fundamental appeal of EVs.

And you don't need to take classes in electrical theory to understand how an EV motor works, or even the deeper differences between brushed or brushless DC motors. Most buyers won't likely notice if their car uses an asynchronous induction motor on the front axle (as most Tesla models do) or synchronous permanent magnet motors (like the Porsche Taycan and Kia EV6).